IBISWorld Platform

Answer any industry question in minutes with our entire database at your fingertips.

In recent years, the German industry for the production and initial processing of lead, zinc and tin has increasingly come under the influence of stricter regulations and increased sustainability requirements. The use of lead has been increasingly restricted due to stricter environmental and occupational health and safety regulations, particularly in primary production, while the focus is increasingly on recycling and closed material cycles. At the same time, zinc production is entirely dependent on imports, with companies facing growing uncertainties in raw material sourcing and therefore pushing for process optimisation and supplier diversification. Tin only accounts for a small proportion of the sector's turnover. There is a clear trend towards the use of secondary raw materials in tin processing, which is supported by scientific evidence of equivalent quality and makes the industry more flexible and less dependent on international supply chains. Industry turnover increased by an average of 3.8% per year between 2020 and 2025, primarily due to the sharp rise in the price of zinc in 2022.In the current year, industry turnover is expected to increase by 0.5% to 2.9 billion euros. The industry for the production and initial processing of lead, zinc and tin in Germany is facing profound upheaval. The production and processing of lead, zinc and tin in Germany is currently characterised by the targeted securing of its international supply of raw materials and innovative process optimisation. Zinc production is based exclusively on imported concentrates, which means that companies are highly exposed to price fluctuations and geopolitical risks. In response to this, market participants are increasingly focusing on diversifying their sources of supply, concluding long-term supply contracts and optimising hydrometallurgical processes, particularly in electrolytic zinc extraction. At the same time, by-products such as sulphuric acid, silver and indium are gaining in importance, as their industrial utilisation opens up additional revenue streams and increases profitability.Between 2025 and 2030, industry turnover is expected to increase by an average of 0.8% per year to €3.1 billion. The industry for the production and initial processing of lead, zinc and tin in Germany is facing profound upheaval. Stricter EU and federal regulations, particularly for lead, are leading to a significant drop in demand in the construction industry and for consumer batteries. Industry companies are increasingly shifting their focus to recycling, exports and industrial applications. At the same time, the industry is benefiting from the energy transition, as tin and zinc are increasingly being used in renewable energies, electromobility and energy storage technologies. Government subsidy programmes such as climate protection agreements enable necessary investments in low-emission technologies and support the switch to sustainable processes. This strengthens competitiveness and opens up new growth opportunities for the German non-ferrous metals industry.

Answer any industry question in minutes with our entire database at your fingertips.

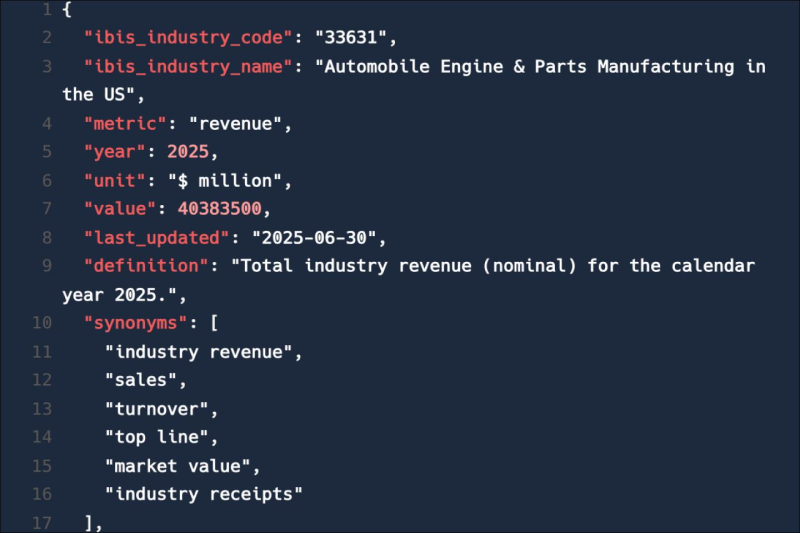

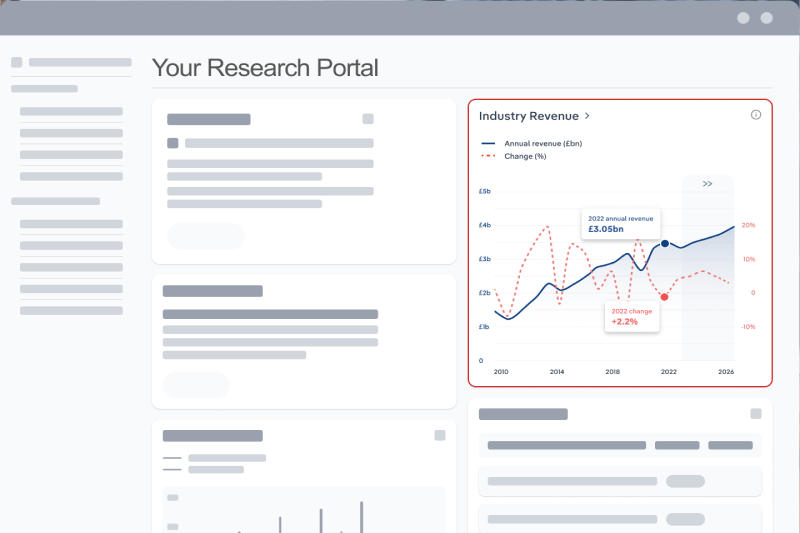

Feed trusted, human-driven industry intelligence straight into your platform.

Streamline your workflow with IBISWorld’s intelligence built into your toolkit.

IBISWorld's research coverage on the Lead, Zinc & Tin Production industry in Germany includes market sizing, forecasting, data and analysis from 2015-2030. The most recent publication was released May 2025.

The Lead, Zinc & Tin Production industry in Germany operates under the WZ industry code C24.43DE. Lead, zinc and tin are among the non-ferrous metals. This industry is concerned with the production of lead, zinc and tin and their alloys in the form of ingots, plates, sheets, strips, profiles, powders, dust, wire, foils or filters from ores or residues and scrap. The casting of these metals is not part of the industry. Related terms covered in the Lead, Zinc & Tin Production industry in Germany include alloying, lot, corrosion, primary lead, secondary lead, wage reduction, semiconductors, extrusion machine and qsl facility.

Products and services covered in Lead, Zinc & Tin Production industry in Germany include Lead in raw form, Lead in processed form and Zinc in raw form.

Companies covered in the Lead, Zinc & Tin Production industry in Germany include Grillo-Werke AG, Nyrstar Stolberg GmbH and Ecobat Resources Germany GmbH.

The Performance chapter covers detailed analysis, datasets, detailed current performance, sources of volatility and an outlook with forecasts for the Lead, Zinc & Tin Production industry in Germany.

Questions answered in this chapter include what's driving current industry performance, what influences industry volatility, how do successful businesses overcome volatility, what's driving the industry outlook. This analysis is supported with data and statistics on industry revenues, costs, profits, businesses and employees.

The Products and Markets chapter covers detailed product and service segmentation, analysis of major markets and international trade data for the for the Lead, Zinc & Tin Production industry in Germany.

Questions answered in this chapter include how are the industry's products and services performing, what are innovations in industry products and services, what products or services do successful businesses offer and what's influencing demand from the industry's markets. This includes data and statistics on industry revenues by product and service segmentation and major markets.

The Geographic Breakdown chapter covers detailed analysis and datasets on regional performance of the Lead, Zinc & Tin Production industry in Germany.

Questions answered in this chapter include where are industry businesses located and how do businesses use location to their advantage. This includes data and statistics on industry revenues by location.

The Competitive Forces chapter covers the concentration, barriers to entry and supplier and buyer profiles in the Lead, Zinc & Tin Production industry in Germany. This includes data and statistics on industry market share concentration, barriers to entry, substitute products and buyer & supplier power.

Questions answered in this chapter include what impacts the industry's market share concentration, how do successful businesses handle concentration, what challenges do potential industry entrants face, how can potential entrants overcome barriers to entry, what are substitutes for industry services, how do successful businesses compete with substitutes and what power do buyers and suppliers have over the industry and how do successful businesses manage buyer & supplier power.

The Companies chapter covers Key Takeaways, Market Share and Companies in the Lead, Zinc & Tin Production industry in Germany. This includes data and analysis on companies operating in the industry that hold a market share greater than 5%.

Questions answered in this chapter include what companies have a meaningful market share and how each company is performing.

The External Environment chapter covers Key Takeaways, External Drivers, Regulation & Policy and Assistance in the Lead, Zinc & Tin Production industry in Germany. This includes data and statistics on factors impacting industry revenue such as economic indicators, regulation, policy and assistance programs.

Questions answered in this chapter include what demographic and macroeconomic factors impact the industry, what regulations impact the industry, what assistance is available to this industry.

The Financial Benchmarks chapter covers Key Takeaways, Cost Structure, Financial Ratios, Valuation Multiples and Key Ratios in the Lead, Zinc & Tin Production industry in Germany. This includes financial data and statistics on industry performance including key cost inputs, profitability, key financial ratios and enterprise value multiples.

Questions answered in this chapter include what trends impact industry costs and how financial ratios have changed overtime.

The Industry Data chapter includes 10 years of historical data with 5 years of forecast data covering statistics like revenue, industry value add, establishments, enterprises, employment and wages in the Lead, Zinc & Tin Production industry in Germany.

More than 6,000 businesses use IBISWorld to shape local and global economies

We were able to supplement our reports with IBISWorld’s information from both a qualitative and quantitative standpoint. All of our reporting now features some level of IBISWorld integration.

IBISWorld delivers the crisp business knowledge we need to drive our business. Whether it be serving up our major clients, winning new business or educating on industry issues, IBISWorld brings real value.

IBISWorld has revolutionised business information — which has proved commercially invaluable to exporters, investors and public policy professionals in Australia and overseas.

When you’re able to speak to clients and be knowledgeable about what they do and the state that they operate in, they’re going to trust you a lot more.

The market size of the Lead, Zinc & Tin Production industry in Germany is €2.9bn in 2026.

There are 19 businesses in the Lead, Zinc & Tin Production industry in Germany, which has declined at a CAGR of 0.0 % between 2020 and 2025.

The Lead, Zinc & Tin Production industry in Germany is likely to be significantly impacted by import tariffs with imports accounting for a high share of industry revenue.

The Lead, Zinc & Tin Production industry in Germany is likely to be significantly impacted by export tariffs with exports accounting for a high share of industry revenue.

The market size of the Lead, Zinc & Tin Production industry in Germany has been growing at a CAGR of 3.8 % between 2020 and 2025.

Over the next five years, the Lead, Zinc & Tin Production industry in Germany is expected to grow.

The biggest companies operating in the Lead, Zinc & Tin Production industry in Germany are Grillo-Werke AG, Nyrstar Stolberg GmbH and Ecobat Resources Germany GmbH

Lead in raw form and Lead in processed form are part of the Lead, Zinc & Tin Production industry in Germany.

The company holding the most market share in the Lead, Zinc & Tin Production industry in Germany is Grillo-Werke AG.

The level of competition is moderate and steady in the Lead, Zinc & Tin Production industry in Germany.